Granulators for profiles

P line

Applications:

EXTRUSION

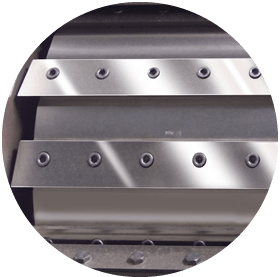

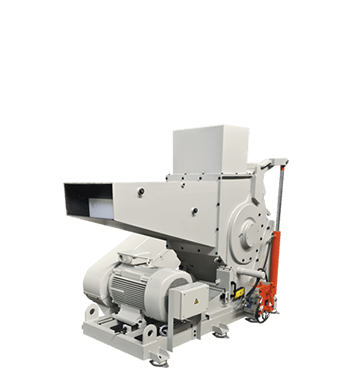

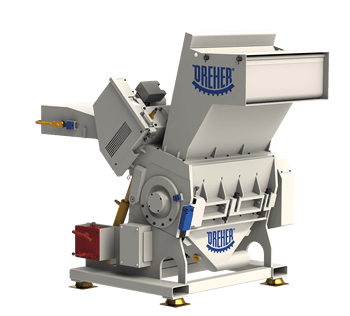

Granulators for profiles S34/52 P line - closed

Granulators for profiles S34/52 P line - closed

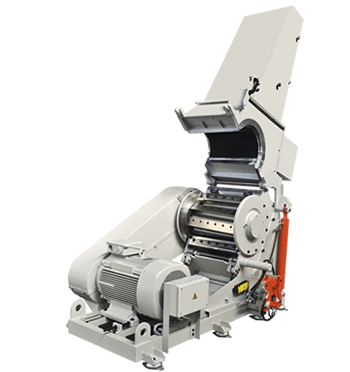

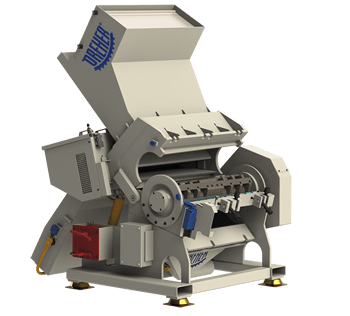

Granulators for profiles S34/52 P - open

Granulators for profiles S34/52 P - open

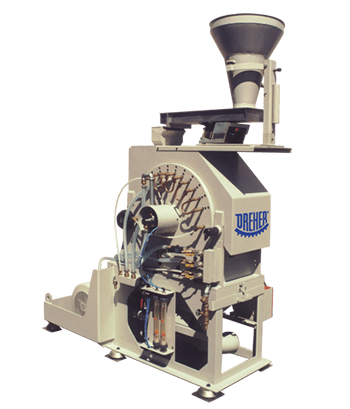

Skeletal Waste Granulators

STR line

Applications:

THERMOFORMING

EXTRUSION

Powder Mills

SF line

Applications:

EXTRUSION