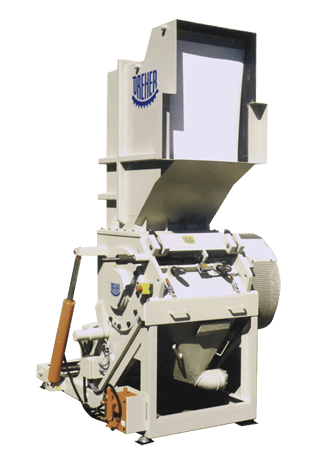

Product Information::

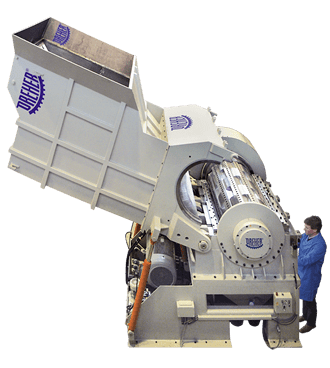

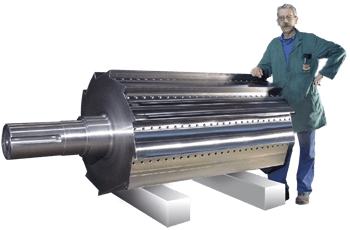

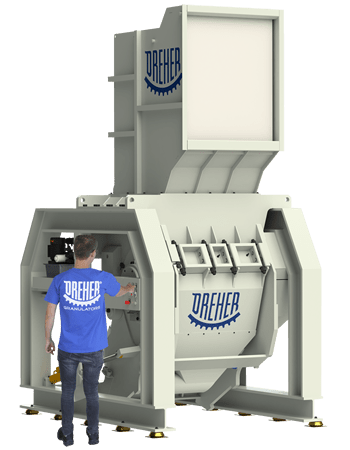

The SRV-system

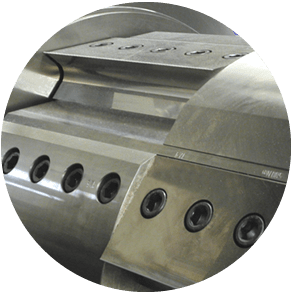

These Heavy-Duty Granulators, have been specially designed for the economical granulation on thick walled sections such as

- tops and tails

- chunks

- extruder discharges

- thick walled sheeds, pipelines, etc.

According to the size of construction, these Granulators are able to process pieces of the toughest materials of more than 400 kg without pre-crushing. Due to the specially designed rotor and the proven cutting blades arrangement, a regular cutting without overloading of drive is assured. These Granulators are also suitable for hot melt granulation. The recycling of plastic scrap material and reject parts can be fully automated by DREHER Granulators. As the result of many years of experience DREHER can provide you with the optimum information to meet your specific requirements when planning complete plants.

RECYCLING

THERMOFORMING

BLOWMOULDING

EXTRUSION

THERMOFORMING

BLOWMOULDING

EXTRUSION

THERMOFORMING

EXTRUSION

FILM-EXTRUSION