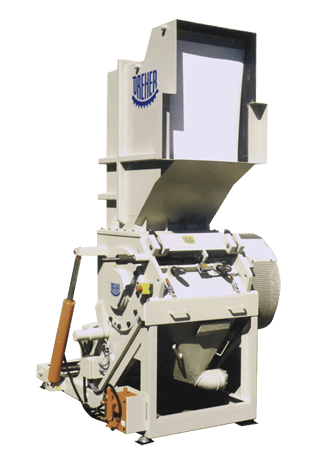

Compact Granulators

Delta line

Applications:

INJECTIONMOULDING

BLOWMOULDING

FILM-EXTRUSION

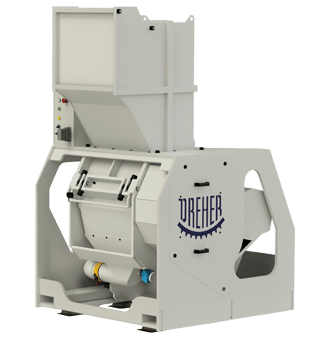

Compact Granulators

DX line

Applications:

THERMOFORMING

BLOWMOULDING

EXTRUSION

Hydraulically opening of the cutting chamber

Compact Granulators

GFS line

Applications:

THERMOFORMING

EXTRUSION

FILM-EXTRUSION